According to the World Nuclear Association, as of February 2020:

- Improved designs of nuclear power reactors are constantly being developed internationally;

- The first so-called Generation III advanced reactors have been operating in Japan since 1996. These have now evolved further;

- Newer advanced reactors now being built have simpler designs which are intended to reduce capital cost. They are more fuel efficient and are inherently safer; and

- Many new designs are small – up to 300 MWe. These are described in a separate information paper.

Several generations of reactors are commonly distinguished. Generation I reactors were developed in 1950-60s, and the last one shut down in the UK in 2015. Generation II reactors are typified by the present US and French fleets and most in operation elsewhere. So-called Generation III (and III+) are the advanced reactors discussed in this paper, though the distinction from Generation II is arbitrary. The first ones are in operation in Japan and others are under construction in several countries. Generation IV designs are still on the drawing board and will not be operational before the 2020s.

Over 85% of the world’s nuclear electricity is generated by reactors derived from designs originally developed for naval use. These and other nuclear power units now operating have been found to be safe and reliable, but they are being superseded by better designs.

Reactor suppliers in North America, Japan, Europe, Russia, China and elsewhere have a dozen new nuclear reactor designs at advanced stages of planning or under construction, while others are at a research and development stage. Fourth-generation reactors are at the R&D or concept stage.

Nuclear power reactors may be, classified into the following two categories:

Conventional Nuclear Reactors:

- Generation I nuclear power reactors were, developed in 1950-1960s, and none of those nuclear reactors are in operation today. These reactors refer to the early prototype and power reactors, such as Shippingport, Magnox, Fermi1, and Dresden; and

- A generation II nuclear power reactor is a design classification for nuclear reactor, and refers to the class of commercial reactors built up to the end of the 1990s. Prototype generation II reactors include the Pressurized Water Reactor (PWR), Canada Deuterium Uranium (CANDU), Boiling Water Reactor (BWR), and Vodo-Vodyanoi Energetichesky Reactor (VVER). These reactors are, typified by the present US fleet and most in operation elsewhere.

Advanced Nuclear Reactors:

- Generation III nuclear reactors are the Advanced Reactors. The first of these reactors are in operation in Japan and others are under construction or ready to be ordered; and

- Generation IV reactor designs are still on the drawing board and will not be operational before 2020 at the earliest.

GENERATION III NUCLEAR POWER REACTORS:

A generation III reactor is a development of any of the generation II nuclear reactor designs incorporating evolutionary improvements in design developed during the lifetime of the generation II reactor designs. These reactors include improved fuel technology, superior thermal efficiency, passive safety systems, and standardized design for reduced maintenance and capital costs.

Third-generation reactors represent the following characteristics:

- A standardized design for each type to expedite licensing, reduce capital cost and reduce construction time;

- A simpler and more rugged design, making them easier to operate and less vulnerable to operational upsets;

- Higher availability and longer operating life—typically 60 years;

- Reduced possibility of core melt accidents;

- Resistance to serious damage that would allow radiological release from an aircraft impact;

- Higher burn-up to reduce fuel use and the amount of waste; and

- Burnable absorbers (“poisons”) to extend fuel life.

The US Nuclear Regulatory Commission (NRC) believes third-generation reactor designers should consider the following:

- Highly reliable, less complex safe shutdown systems, particularly ones with inherent or passive safety features;

- Simplified safety systems that allow more straightforward engineering analysis, operate with fewer operator actions and increase operator comprehension of reactor conditions;

- Concurrent resolution of safety and security requirements, resulting in an overall security system that requires fewer human actions;

- Features that prevent a simultaneous breach of containment and loss of core cooling from an aircraft impact, or that inherently delay any radiological release, and;

- Features that maintain spent fuel pool integrity following an aircraft impact.

The other major differences between conventional and advanced nuclear power reactors include:

- Many third-generation reactors incorporate passive or inherent safety features that require no active controls or operational intervention to avoid accidents in the event of malfunction, and may rely on gravity, natural convection or resistance to high temperatures. Traditional reactor safety systems are, “active” in the sense that they involve electrical or mechanical operation on command. Some engineered systems operate passively, e.g. pressure relief valves. They function without operator control and despite any loss of auxiliary power. Both require parallel redundant systems. Inherent or full passive safety depends only on physical phenomena such as convection, gravity or resistance to high temperatures, not on functioning of engineered components;

- Some third-generation reactors will be designed for load following. While most French reactors today are, operated in that mode to some extent, the European Pressurized Reactors (EPR) design has better capabilities. It will be able to maintain its output at 25 percent and then ramp up to full output at a rate of 2.5 percent of rated power per minute up to 60 percent output and at 5 percent of rated output per minute up to full rated power. This means that potentially the unit can change its output from 25 percent to 100 percent in less than 30 minutes, though this may be at some expense of wear and tear; and

- Many of third-generation reactors are larger than, predecessors. Increasingly they involve international collaboration.

However, certification of designs is on a national basis, and is safety-based. In Europe, there are moves towards harmonized requirements for licensing. In Europe, reactors may also be, certified according to compliance with European Utilities Requirements (EUR) of 12 generating companies, which have stringent safety criteria. The EUR are, basically, a utilities’ wish list of some 5000 items needed for new nuclear plants. Plants certified as complying with EUR include Westinghouse AP1000, Gidropress’ AES-92, Areva’s EPR, GE’s ABWR, Areva’s SWR-1000, and Westinghouse BWR 90.

Here is a table, which illustrates the configuration of Generation III Advanced Nuclear Power Reactors:

| No | Description |

| 1. | LIGHT WATER REACTORS (LWR): |

| 1.1 | European Pressurized Water Reactor (EPR); |

| 1.2 | Advanced Passive 1000 (AP1000); |

| 1.3 | Advanced Boiling Water Reactors (ABWR); |

| 1.4 | Economic & Simplified Boiling Water Reactors (ESBWR); |

| 1.5 | Advanced Pressurized Water Reactors (APWR); |

| 1.6 | Advanced Pressurized Reactors 1400 (APR1400); |

| 1.7 | Atmea1; |

| 1.8 | Kerena/Karena; |

| 1.9 | AES-92,V392; |

| 1.10 | AES-2006; |

| 1.11 | MIR-1200; |

| 1.12 | International Reactor Innovation and Secure (IRIS); |

| 1.13 | VBER-300; and |

| 2. | HEAVY WATER REACTORS (HWR): |

| 2.1 | Enhanced CANDU-6(EC6); |

| 2.2 | Advanced CANDU Reactors (ACR); |

| 2.3 | Advanced Heavy Water Reactors (AHWR); |

| 3. | HIGH TEMPERATURE GAS-COOLD REACTORS (HTGR): |

| 3.1 | HTR-PM; |

| 3.2 | Pebble Bed Modular Reactors (PBMR); and |

| 3.3 | Gas Turbine – Modular Helium Reactors (G7-MHR). |

| 4. | FAST NEUTRON REACTORS (FNR): |

| 4.1 | Fast Breeder Reactors (FBR); |

| 4.2 | Japan Standard Fast Reactors (JSFR); |

| 4.3 | BN-600; |

| 4.4 | BN-800; |

| 4.5 | BREST; |

| 4.6 | European Lead-Cooled System (ELSY); |

| 4.7 | PRISM; |

| 4.8 | KALIMER. |

This chapter will cover only Light Water Reactors (LWR):

- LIGHT WATER REACTORS (LWR):

The light water reactor or LWR is, defined as a type of thermal reactor that uses light water as a coolant and neutron moderator as opposed to heavy water as a coolant/moderator. Thermal reactors are the most common type of nuclear reactors, and light water reactors are the most common type of thermal reactor. There are the following three types of LWR:

- The Pressurized Water Reactor (PWR);

- The Boiling Water Reactor (BWR); and

- The Supercritical Water Reactor (SWR).

Here is a brief description for each nuclear reactor under this category and these descriptions are, derived from the World Nuclear Association:

Areva NP has developed a large (4590 MWt, typically 1750 MWe gross and 1630 MWe net) European pressurized water reactor (EPR)), which was confirmed in mid-1995 as the new standard design for France and received French design approval in 2004. It is a 4-loop design derived from the German Konvoi types with features from the French N4, and is, expected to provide power about 10 percent cheaper than the N4. It will operate flexibly to follow loads, have fuel burn-up of 65 GWd/t and a high thermal efficiency, of 37 percent, and net efficiency of 36 percent. It is capable of using a full core load of MOX. Availability is, expected to be 92 percent over a 60-year service life. It has four separate, redundant safety systems rather than passive safety.

The first EPR unit is, being built at Olkiluoto in Finland, the second at Flamanville in France, the third European one will be at Penly in France, and two further units are under construction at Taishan in China. A US version, the US-EPR, was, submitted for US design certification in December 2007, and this is, expected to be granted early 2012. The first unit (with 80 percent US content) is, expected to be grid connected by 2020. It is, now known as the Evolutionary PWR (EPR). Much of the one million person-hours, of work involved in developing this US EPR are making the necessary changes to output electricity at 60 Hz instead of the original design’s 50 Hz. The main development of the type is to be through UniStar Nuclear Energy, but other US proposals also involve it.

1.2 Advanced Passive 1000 (AP1000):

The AP1000, based on the proven performance of Westinghouse-designed PWR, is an advanced 1154 MWe nuclear power plant that uses the forces of nature and simplicity of design to enhance plant safety and operations and reduce construction costs. The AP1000 features proven technology, innovative passive safety systems and offers:

- Unequaled safety;

- Economic competitiveness; and

- Improved and more efficient operations.

The AP1000 builds and improves upon the established technology of major components used in current Westinghouse-designed plants with proven, reliable operating experience over the past 50 years. These components include:

- Steam generators;

- Digital instrumentation and controls;

- Fuel;

- Pressurizer; and

- Reactor vessels.

The Westinghouse AP1000 is a 2-loop PWR that has evolved from the smaller AP600, one of the first Generation III reactor designs certified by the US NRC, in 2005. Simplification was a major design objective of the AP1000, in overall safety systems, normal operating systems, the control room, construction techniques, and instrumentation and control systems provide cost savings with improved safety margins. Core damage frequency is 5×10-7. It is being, built in China, and the Vogtle site is being, prepared for initial units in the USA.

The first four units are on schedule, being, assembled from modules. It is quoted as 1200 MWe gross and 1117 MWe net (3400 MWt), though 1250 MWe gross in China. Westinghouse earlier claimed a 36-month, construction time to fuel loading, but the first ones being built in China are on a 51-month timeline to fuel loading, or 57-month schedule to grid connection.

1.3 Advanced Boiling Water Reactors (ABWR):

The advanced boiling water reactor (ABWR) is, derived from a General Electric design. Two examples built by Hitachi and two by Toshiba are in commercial operation in Japan (1315 MWe net, but two down-rated to 1108 and 1212 MWe net), with another two under construction there and two in Taiwan. Four more are, planned in Japan and another two in the USA. It is basically a 1380 MWe (gross) unit (3926 MWt in Toshiba version), though GE Hitachi quote 1350-1600 MWe net and Hitachi is also developing 600, 900 and 1700 MWe versions of it. Toshiba outlines development from 1350 MWe class of 1600-1700 MWe class as well as 800-1000 MWe class derivatives. Tepco is funding the design of a next generation BWR, and the ABWR-II is, quoted as 1717 MWe.

The first four ABWR, were each built in 39 months on a single-shift basis. Though GE and Hitachi have subsequently joined up, Toshiba retains some rights over the design, as does Tepco. Both GE-Hitachi and Toshiba (with NRG Energy in USA) are marketing the design. Design life is 60 years.

The following highlights Technology Enhancements that Improve Performance:

- Reactor internal pumps –improved safety and performance by eliminating external recirculation systems;

- Integrated containment and reactor building–improved seismic response, compact, and easier to construct;

- Compact reactor building–less construction material and shorter construction times;

- Optimized modularization–module designs refined and proven in real installations;

- Sophisticated control systems–fully digital, providing reliable and accurate plant monitoring, control, and diagnostics; and

- High integrity fuel, improved water chemistry, and radiation source elimination–reduced radwaste and occupational exposure.

Benefits and Features of the ABWR over Previous BWR Designs include:

- Improved safety, reliability, operability, and maintainability;

- Demonstrated reduction in capital and O & M costs;

- Proven advanced reactor technology and performance enhancements; and

- Shorter construction time of approximately 39 months from first concrete to first fuel load proven in Japan.

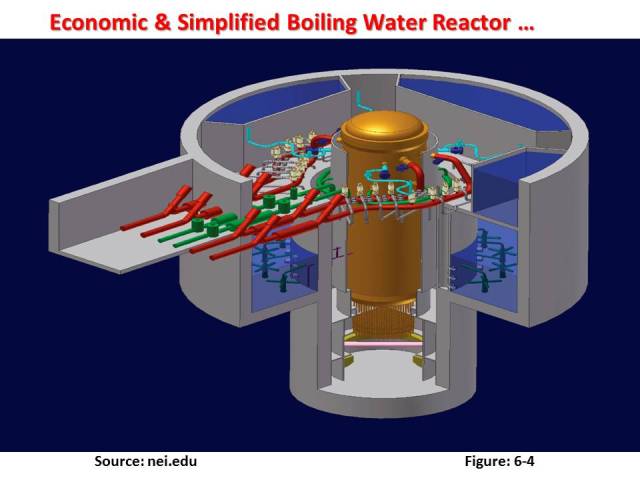

1.4 Economic and Simplified Boiling Water Reactors (ESBWR):

GE Hitachi Nuclear Energy’s ESBWR is a Generation III+ technology that utilizes passive safety features and natural circulation principles and is essentially an evolution from a predecessor design, the SBWR at 670 MWe.

GE says it is safer and more efficient than earlier models, with 25 percent fewer pumps, valves and motors. The ESBWR will produce approximately 1600 MWe gross, 1520 MWe net, depending on site conditions, and has a design life of 60 years. It was more fully known as the Economic & Simplified BWR (ESBWR) and leverages proven technologies from the ABWR. The ESBWR is in advanced stages of licensing review with the US NRC for GE Hitachi and is on schedule for full design certification in 2010-11. Core damage frequency is, quoted as 1×10-8.

GEH is selling this alongside the ABWR, which it characterizes as more expensive to build and operate, but proven. ESBWR is more innovative, with lower building and operating costs and a 60-year life.

The core is made shorter than conventional BWR plants in an effort to reduce the pressure drop over the fuel, thereby enabling natural circulation. There are 1132 bundles and the thermal power is 4500 MWth. The nominal summertime output is, rated at 1575-1600 MWe, yielding an overall plant efficiency of 35 percent.

In the case of an accident, the ESBWR can remain stabilized for 72 hours without any operator action. Below the vessel, there is a piping structure, which, allows for cooling of the core during a very severe accident. These pipes divide the molten core and cool it with water flowing through the piping. The probability of radioactivity release to the atmosphere is several orders of magnitude lower than conventional nuclear power plants, and the building cost is 60-70 percent of other LWR.

The energy production cost is lower than other plants due to:

- Lower initial capital cost; and

- Lower operational and maintenance cost.

1.5 Advanced Pressurized Water Reactors (APWR):

A prudent development of APWR has been, performed, based on the results of the third improvement and standardization program by joint effort of the public and private sectors, which began in 1982, adopting experiences in operation and maintenance of conventional PWR plants and the state of the art technologies, and incorporating the technologies of further advancement. For APWR, MHI strived to achieve the harmonization with the environment, enhanced safety, improved reliability and economy, and enhanced operability and maintainability to meet the need of the times. The APWR plants were, selected for Tsuruga units 3 and 4, scheduled to begin operation in 2016 and 2017.

Mitsubishi’s large APWR (1538 MWe Gross) – advanced PWR – was developed in collaboration with four utilities (Westinghouse was earlier involved). The first two are, planned for Tsuruga, coming on line from 2016. It is a 4-loop design with 257 fuel assemblies, is simpler, combines active and passive cooling systems to greater effect, and has over 55 GWd/t (and up to 62 GWd/t) fuel burn-up. It will be the basis for the next generation of Japanese PWR. The APWR+ is 1750 MWe and has full-core MOX capability.

The US-APWR will be 1700 MWe gross, about 1620 MWe net, due to longer (4.3m) fuel assemblies, higher thermal efficiency (39 percent) and has 24-month refueling cycle. US design certification application was in January 2008 with approval expected in 2011 and certification mid-2012. In March 2008, MHI submitted the same design for EUR certification, as EU-APWR, and it will join with Iberdrola Engineering & Construction in bidding for sales of this in Europe. Iberdrola would be responsible for building the plants.

The Japanese government is, expected to provide financial support fort US licensing of both US-APWR and the ESBWR. The Washington Group International will be involved in US developments with Mitsubishi Heavy Industries (MHI). The US-APWR has been, selected by Luminant for Comanche Peak, Texas, and when the COL application for the new reactors was, lodged Luminant and MHI announced a joint venture to build and own the twin-unit plant. This Comanche Peak Nuclear Power Co is 88 percent Luminant, 12 percent MHI.

1.6 Advanced Pressurized Reactor 1400 (APR1400):

South Korea’s APR-1400 Advanced PWR design has evolved from the US System 80+ with enhanced safety and seismic robustness and was earlier known as the Korean Next-Generation Reactor. Design certification by the Korean Institute of Nuclear Safety was, awarded in May 2003.

It is 1455 MWe gross, 1350-1400 MWe net (3983 MWt) with 2-loop primary circuit. The first of these is under construction – Shin-Kori-3 & 4, expected to be operating in 2013. Fuel has burnable poison and will have up to 55 GWd/t burn-up, refueling cycle c 18 months, outlet temperature 324ºC. Projected cost at the end of 2009 was US$ 2300 per kilowatt, with 48-month construction time. Plant life is 60 years; seismic design basis is 300 Gal. A low-speed (1800 rpm) turbine is, envisaged. It has been chosen as the basis of the United Arab Emirates nuclear program based on cost and reliable building schedule, and an application for US Design Certification is planned in 2012.

Based on this there are plans for an EU version (EU-APR1400) and a more advanced 1550 MWe (gross) Generation III+ version, the APR+. In addition, some of the APR features are, being incorporated into a development of the OPR-1000 to give an exportable APR-1000.

The APR1400 includes safety features not found in conventional reactors. For example, the design includes a missile shield to defend against both an internal and external missile attack. The design even includes seismic restraints and improved materials that would prevent damage to the reactor in the event of an earthquake.

The basic design of the reactor vessel of the APR1400 is, shown on Korea Hydro & Nuclear Power’s (KHNP’s) website. The reactor vessel contains the nuclear fuel that drives the fission process in the reactor. In order to remove heat produced by the fission process, water is pumped into the reactor vessel through four inlet nozzles, and exits through two outlet nozzles. The outlet nozzles are, placed vertically higher than the inlet nozzles in order to promote natural circulation in the event of a loss of pumps.

The nuclear fuel for the APR1400 was, designed by Korea Nuclear Fuel. The APR1400 uses uranium dioxide, processed from enriched uranium-235. To manufacture the nuclear fuel, the uranium dioxide must first be, processed into a powder form. It is, then pressed into cylindrical pellets of approximately 10mm in length, 8mm in width, and weighing 5.2 grams.

Approximately 365 pellets are then stacked end-to-end inside a hollow fuel rod made of a zirconium-niobium alloy.

1.7 Atmea1 Reactors:

The Atmea1 is developed by the Atmea joint venture established in 2006 by Areva NP and Mitsubishi Heavy Industries to produce an evolutionary 1150 MWe net 93150 MWt) three-loop PWR using the same steam generators as EPR. This has extended fuel cycles, 37 percent thermal efficiency, 60-year life, and the capacity to use mixed-oxide fuel only.

Fuel cycle is flexible 12 to 24 months with short refueling outage and the reactor has load following and frequency control capability. The partners are submitting this to French regulator ASN for safety review, which is, expected to be complete in late 2011. The reactor is regarded as mid-sized relative to other generation III units and will be, marketed primarily to countries embarking upon nuclear power programs.

The ATMEA1 responds to market requirements for a mid-sized pressurized water reactor while offering solid Generation III+ safety features and optimal return on investment

Utilities will benefit not only from innovative, proven nuclear technologies from AREVA and MHI, but also from the extensive in-house production capacity and high manufacturing reliability of these two companies. This is particularly relevant given the rapid growth anticipated in the nuclear market over the coming years.

ATMEA1 meets Generation III+ safety objectives. ATMEA1 has three divisions of reliable safety systems with 100 percent capacity for each division. A fourth train is, provided to allow partial online maintenance during power operation.

ATMEA1 safety systems are characterized by:

- Strict separation between each of the safety systems and between safety and operational I&C systems;

- Optimized balance between passive and active systems;

- Advanced accumulators;

- Probability of core damage and large radiological release a factor of 10 lower than conventional PWR;

- In the unlikely event of a severe accident, the core catcher will passively collect, retain, and cool core debris in a specially designed area inside the reactor containment building;

- Hydrogen-control technology will prevent hydrogen accumulation;

- Complies with regulations of European countries and with expected US NRC regulations; and

- Safety facilities protected, by segregation or concrete to secure all required safety functions.

ATMEA1 is compatible with most grids:

- 1,000-1,150 MWe reactor that fits most power grids;

- ATMEA1 is available for both 50Hz, 60Hz;

- Grid stabilizing features include extended load-follow capacity, frequency control mode, and quick return to full power; and

- ATMEA1 design is flexible enough to match a range of heat-sink conditions.

The highly-energy effective design reduces cooling water consumption and allows a lower heat up of cooling water. Design available for high-seismic areas:

- Reducing environmental impact:

- Core design optimized to burn fuels more efficiently and generate less waste;

- More efficient electricity generation increases energy harvested per pound of uranium; and

- Amount of spent fuel generated expected to be around 15 cent less than a Generation II plant.

1.8 Kerena/Karena:

Together with German utilities and safety authorities, Areva NP is also developing another evolutionary design, the Kerena, a 1290 MWe gross, 1250 MWe net (3370 MWt) BWR with 60-year design life formerly known as SWR1000. The design, based on the Gundremmingen plant built by Siemens, was completed in 1999 and US certification was sought, but then deferred. As well as many passive safety features, the reactor is simpler overall and uses high-burnup fuels enriched to 3.54 percent, giving it refueling intervals of up to 24 months. It has 37 percent net efficiency and is ready for commercial deployment.

The primary objective safety objective of the design of MERENA is to rule out core damage at any pressure including high pressure by using an efficient defence in depth safety concept with redundant and diverse active and passive systems for accident detection and control.

The passive safety KERENA plant is uniquely suited to in-vessel retention because it contains features that promote external cooling of the reactor vessel:

- The reactor cavity can be flooded to submerge the vessel 12m in water intentionally drained from the flooding pool;

- The pressure equalization of vessel containment and the 12m submergence of the vessel create higher static pressure outside the vessel lower head wall than on the inside over the predominant surface of the lower head thus preventing creep failure of the wall itself and any melt release outside the vessel;

- The reactor vessel insulation design provides an engineered pathway for water-cooling of the vessel and for venting steam from the reactor cavity into the upper part of the containment where the four containment cooling condensers condense it;

- The lower head penetrations are prevented from large-scale relocation (Larger than 2cm) by design measures assuring the anchoring of penetrations to the 70 tons support plate below the reactor. The anchoring allows the thermal extensions in normal operation; and

- The support plate may serve as a secondary core catcher, a feature that is beyond the KERENA sever accidental management concept.

1.9 AES-92, V392 Nuclear Reactors:

Gidropress late-model VVER-1000 units with enhanced safety (AES 92 & 91 power plants) are, being built in India and China. Two more are, planned for Belene in Bulgaria. The AES-92 is, certified as meeting EUR, and its V-392 reactor is, considered Generation III.

Bulgaria decided at the end of 2006 to build a nuclear power plant in Belene. Atomstroyexport (ASE1) won the tender with a reactor model called AES-922. The AES-92 is an updated VVER 1000/3203, which is the Soviet-type pressurized light water reactor known in Russia as the third generation VVER 1000 reactor (alias VVER-1000/V392). ASE intends to deliver two of these 1000 MW reactors to Bulgaria.

Research showed that the AES-92 is a customized VVER-1000/V-392 model known under many confusing abbreviations. Only one very similar type was, built in China (called AES-91, also based on the VVER 1000/320 series). However, there is no operational experience with this AES reactor either (NPP Tianwan-1/2, installed capacity 2×1060 MW, design life 40 years), since the first unit went into full power operation only in January 2007. It is also not realistic to think that there will be reliable information regarding operational experience available within the next few years for the Chinese reactor. In addition, there is no safety assessment on this reactor model available.

The Chinese AES-91 or 92 (VVER-1000/V-428 according to the Russian engineering company Gidropress) was developed based on the design V-392. According to information of Gidropress, who is responsible for the design, the Chinese reactor fulfills the recommendations of the IAEA programme on upgrading and improving safety of operating VVER-1000 reactors.

The only other comparable reactor, although of a slightly different design, is the AES-91 at Kudankulam in India. This AES reactor is currently under construction and therefore does not provide any data on operational experience. Another AES model, carrying the same number and name as is used in the Belene EIA documentation, is under construction at the Bushehr site in Iran.

AES-92 – According to ASE representatives the AES-92 combines active and passive safety systems, features an “economically advantageous” safety systems organization, and uses instrumentation and control (I&C) of a new generation. Framatome ANP would supply the I&C system. (Teleperm system- originally by Siemens is used also on the Tianwan AES-92).

Framatome ANP will also deliver electrical systems, heating, ventilation, and air conditioning systems, safety systems including hydrogen recombiners and monitors, and containment prestress system – similar to Framatome ANP’s scope at Tianwan.

Technical data of the EIA documentation confirm that the proposed AES-92 VVER 1000 reactor is in some parts improved compared to the VVER 320 reactor. The AES reactor has more backup systems for safe shutdown and cooling the reactor than the old VVER 1000 version. However, a lifetime of 60 years is a challenge for the material, and it is not sure that it can be realized safely. It seems that critiques of the original VVER 1000/320 system by Western national regulatory authorities and technical support organizations have been considered in the new VVER 1000 design. However, it is not possible to assess the safety level of these reactors without more detailed information on the design and the material used for fuel rods, the reactor vessel and other components than was provided in the EIA documentation on Belene.

Third generation VVER 1000 / V- 392: New design features of VVER 1000 reactors were, developed by the Russian reactor design and construction company GIDROPRESS in cooperation with western institutions. The cooperation concerned in particular the safety improvement, the involved institutions and enterprises were SIEMENS and GRS from Germany; FRAMATOME and ELECTRICITE DE FRANCE International from France and Fortum Engineering Ltd. from Finland. The outcome is the following improved VVER 1000 reactors:

- VVER 91: In 1989, Finland and the Soviet Union started a development project for a VVER 1000 version that would meet stringent Finnish nuclear design requirements. “on paper, the Soviet VVER 91 design is among the world’s most advanced light water NPPs” (NEI 1997); and

- VVER 92: Development of a new VVER-1000 design, the VVER-92, was expected to be carried out with Western assistance. (NEI 1997) and deliver a NPP which should be cheap, simple and safe. “The VVER-92 incorporated what one Finnish nuclear expert called “radically simplified” plant systems that included active safety systems, a reduced-power reactor core, and a double containment structure surrounding the nuclear reactor.” (NEI 1997).

1.10 AES-2006:

A third-generation standardized VVER-1200 reactor of 1170 MWe net, possibly 1290 MWe gross in the AES-2006 plant is an evolutionary development of the well-proven VVER-1000 in the AES-92 plant, with longer life (50, not nominal 30 years), greater power, and greater efficiency (36.56 percent instead of 31.6 percent).

The lead units are being, built at Novovoronezh II, to start operation in 2012-13 followed by Leningrad II for 2013-14. An AES-2006 plant will consist of two of these OKB Gidropress reactor units expected to run for 50 years with capacity factor of 90 percent. Overnight capital cost was, said to be US$ 1200/kW and construction time 54 months. They have enhanced safety including that related to earthquakes and aircraft impact with some passive safety features, double containment and core damage frequency of 1×10-7.

Atomenergoproekt say that the AES-2006 conforms to both Russian standards and European Utilities Requirements (EUR). In Europe the basic technology is being called the Europe-tailored reactor design, MIR-1200 (Modernized International Reactor) with some Czech involvement.

The VVER-1500 model was being developed by Gidropress. It will have 50-60 MWd/t burn-up and enhanced safety, giving 1500 MWe from 4250 MWt. Design was, expected to be complete in 2007 but this schedule has slipped in favour of the evolutionary VVER-1200.

A typical AES-2006 plant will be a twin set-up with two of these OKB Gidropress reactor units expected to run for 50 years with capacity factor of 90 percent. Construction time is, quoted as 54 months. They have enhanced safety including that related to earthquakes and aircraft affect with some passive safety features, double containment and lower core damage frequency. In Europe, the basic technology is being called the Europe-tailored reactor design, MIR-1200 (Modernized International Reactor), and bid for Temelin 3 & 4, Turkey and Finland.

1.11 MIR-1200:

“MIR. 1200” International Consortium is currently participating in the bidding process for “Temelin” 3, 4 NPP constructions. It is the construction of the second phase of Czech nuclear power plant – by the decision of MSV-2010 organizers – that became the main subject of the “Completion of “Temelin” NPP – chance for Czech industry” conference that was held within the scope of the exhibition.

On behalf of “MIR-1200” International Consortium Miroslav Fiala, Board Chairman and CEO of SKODA JS A.S., Consortium Leader Company, spoke at the conference. His report is devoted to the new opportunities that Consortium’s joint proposal will provide to Czech entrepreneurs if Consortium takes part in the construction of “Temelin” NPP. In the tender specification, a special priority is given to the guarantee to localize 70 percent of equipment supplies, works and services at Czech facilities. This proposal is real since it is, built upon the similar cooperation pattern between Czech Republic and Russia in the area of nuclear power projects. As part of this cooperation two operating NPPs in Czech Republic – “Dukovani” and the first phase of “Temelin” have been constructed. Crucial part of the equipment supplies, works and services was, brought from Czech Republic. This cooperation pattern provides the basis for “MIR. 1200” project today.

“MIR. 1200” Project represents the proven cooperation pattern of the highest rank, Miroslav Fiala believes. – It is based, upon the long-term cooperation of Czech, Russian, European and international companies that are the leading ones in their technological segments. This project is the continuation of the long-term experience of construction and operation of Czech and Slovak nuclear power industry. The project will ensure a further development of knowledge, production and human resources for the wide range of Czech Republic’s industry branches.

“MIR. 1200” Consortium will offer Czech companies the key share of works at the completion of “Temelin” NPP along with the real participation in projects in the third countries. At the same time, Consortium is ready to take part in the improvement of Czech technical education system and support the training of a sufficient number of young professionals by the educational institutions of the country for the forthcoming Renaissance of Czech Republic’s nuclear power industry.

1.12 International Reactor Innovative and Secure (IRIS):

International Reactor Innovative and Secure (IRIS) is a Generation IV reactor design made by an international team of companies, laboratories, and universities and coordinated by Westinghouse.

IRIS is, hoped to open up new markets for nuclear power and make a bridge from Generation III reactor to Generation IV reactor technology. The design is not yet specific to reactor power output. Notably, a 335 MW output has been proposed, but it could be tweaked to be as low as a 100 MW unit.

IRIS is a smaller-scale design for a Pressurized Water reactor (PWR) with an integral reactor coolant system layout, meaning the steam generators, pressurizer, control rod drive mechanisms, and reactor coolant pumps are all located within the reactor pressure vessel. This causes it to have a larger pressure vessel than an ordinary PWR despite a lower power rating, the size is more comparable to that of an ABWR.

Fuel is initially similar to present LWR with 5 percent enrichment and burnable poison; in fact, fuel assemblies are “identical to those … in the AP1000″. These would have burn-up of 60 GWd/t with fuelling interval of 3 to 3.5 years, but IRIS is, designed ultimately for fuel with 10 percent enrichment and 80 GWd/t burn-up with an 8-year cycle, or equivalent MOX core. The core has low power density. IRIS could be, deployed in the next decade, and US design certification is at pre-application stage. Estonia has expressed interest in building a pair of them. Multiple modules are, expected to cost US$ 1000-1200 per kW for power generation, though some consortium partners are interested in desalination, one in district heating.

1.13 VBER-300:

OKBM’s VBER-300 PWR is a 295-325 MWe unit (917 MWt) developed from naval power plants and was originally envisaged in pairs as a floating nuclear power plant.

It is, designed for 60-year life and 90 percent capacity factor. It now planned to develop it as a land-based unit with Kazatomprom, with a view to exports, and the first unit will be, built in Kazakhstan. The VBER-300 is a proposed compact Russian Pressurized Water Reactor (PWR) of 300-MWe or more generating capacity designed for remote locations. In particular, it has been, proposed for use on the Russian Floating Nuclear Power Station (two reactors on a 49,000-tonne barge).

The reactor has been, proposed for use in water desalination as well as for electric generation. The VBER-300 and the similar-sized VK300 are, more fully described in the Small Nuclear Power Reactors section.

Resources:

- World Nuclear Association: Advanced Nuclear Power Reactors;

- Advanced Nuclear Energy Systems;

- GE Hitachi Nuclear Energy;

- Wikipedia: Economic Simplified Boiling Water Reactor;

- ATMEA: The ATMEA1 Reactor;

- Multiphase Flow Dynamics 4 – Review;

- AES-92 for Belene;

- MIR-1200;

- Wikipedia: International Reactor Innovative and Secure;

- Wikipedia: Heavy Water Reactors.

This chapter was published on “Inuitech – Intuitech Technologies for Sustainability” on April 8, 2011; and

This chapter was updated on 10 June 2020